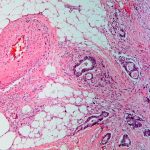

Step by step, researchers have for years been working to re-engineer the biochemical pathway that poppies use to make opioids, such as morphine, and transplant it into yeast. Finally, they have, according to a study published today (August 13) in Science. Stanford University’s Christina Smolke and her colleagues described an engineered strain of Saccharomyces cerevisiae that uses 21 enzymes from plants, mammals, bacteria, and yeast to convert a sugar into thebaine, a compound that can be chemically converted into drugs such as codeine and oxycodone.

“The science is first class,” said Ian Graham, a geneticist at the University of York, U.K., who was not involved in the study. “It’s the first time an entire pathway from sugar to morphinans has been stitched together.”

The report follows several recent studies in which scientists successfully assembled the last few segments of the pathway, including those required to make the intermediate, (S)-reticulum from the amino acid, tyrosine. Most recently, researchers isolated the last piece of the puzzle from opium poppies (Papaver somniferum), an enzyme that converts (S)-reticuline into the morphine precursor (R)-reticuline. For the present study, Smolke and her colleagues used a different variant of the same enzyme, which they independently identified and constructed using a publicly available genome sequence of the Iranian poppy (P. bracteatum).

Even with all of the pieces of the biosynthetic pathway assembled, however, Smolke said simply stringing them together wasn’t enough to efficiently produce thebaine. Her group also had to modify the central metabolism of S. cerevisiae to divert carbon flux toward making tyrosine and its precursors, “so that you’re starting with more going through at the early steps,” she said.

The researchers also had to deal with a major bottleneck—an enzyme that reduced the efficiency of the pathway 100-fold. It took them a couple of years to tackle this problem, which stemmed from incorrect glycosylation and other post-translational modifications of the enzyme. “The yeast were actually misreading the directions for how to make it,” Smolke said.

When they replaced a portion of the protein with the same region from a similar plant protein, the researchers found that the enzyme folded and embedded into intracellular membranes correctly, jump starting the efficiency of the opioid pathway.

Still, Smolke said, the process is not yet ready to be scaled up. The yield of each cell must be improved 100,000 times before it would be economically feasible to grow opioid-producing yeast commercially such that it might compete with poppy-based production. But she doesn’t think it will take long to get there. “There’s a next set of steps and there’s a pretty good sense of what those next things should be,” she said. “It’s not going to be a decade and it’s not going to be five years.”

Smolke and some of her colleagues have established a company to continue optimizing the process, which she said could one day use 500 times less land to produce the same amount of drugs as poppies.

According to Graham, however, this calculation may underestimate the potential of commercial poppy production by about 50 fold. “We need to be realistic when making a comparison of what plants can actually produce,” he said.

Looking beyond the question of commercial viability, some researchers have raised questions about the risk of the engineered yeast inspiring “home-brewed” opiates. In a preprint also released today (August 13) on bioRxiv, Smolke’s group addresses these concerns. In its current form, grown under home-brew conditions, this strain of yeast doesn’t make thebaine—it produces only a miniscule amount of reticuline, she and her colleagues show.

But as the yeast strain and pathway are optimized, this could change. “If they’re going to take this to a commercial level, you’re going to have strains that are producing high levels of these molecules,” said Vincent Martin, a microbiologist at Concordia University in Montreal, who is also building the opioid pathway in yeast for use in drug discovery but was not involved in the work. “We can build and engineer strains much faster than we used to be able to, so I would throw a caution out there to not underestimate how fast this can move forward.”

Smolke said that continuing to monitor the feasibility of home-brewed opioids as the process improves will bring data to the conversation and help clarify the real concerns. “That’s something we can test and monitor as we go forward.”

Martin and Smolke agreed that continued communication with government regulators is key.

“I don’t want to see the technologies slowed down because regulators and governments are not prepared,” said Martin.

RSS